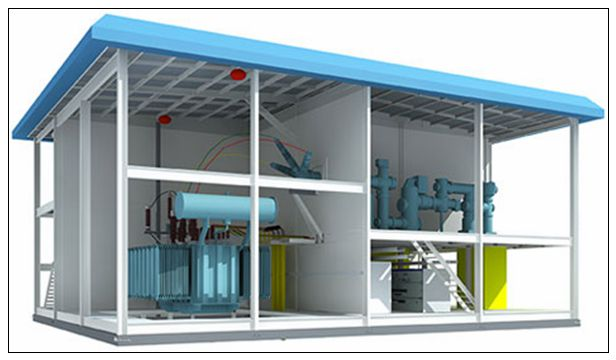

The pre-installed large switchgear station integrates primary and secondary electrical equipment within a factory-assembled, movable, sealed, moisture-proof, and corrosion-resistant double-layer enclosure. This innovative switchgear station model realizes the "Four Modernizations": integration of primary and secondary systems, modular assembly, in-factory pre-installation, and simplified on-site construction—significantly shortening construction cycles, reducing project costs, and enhancing grid operation reliability.

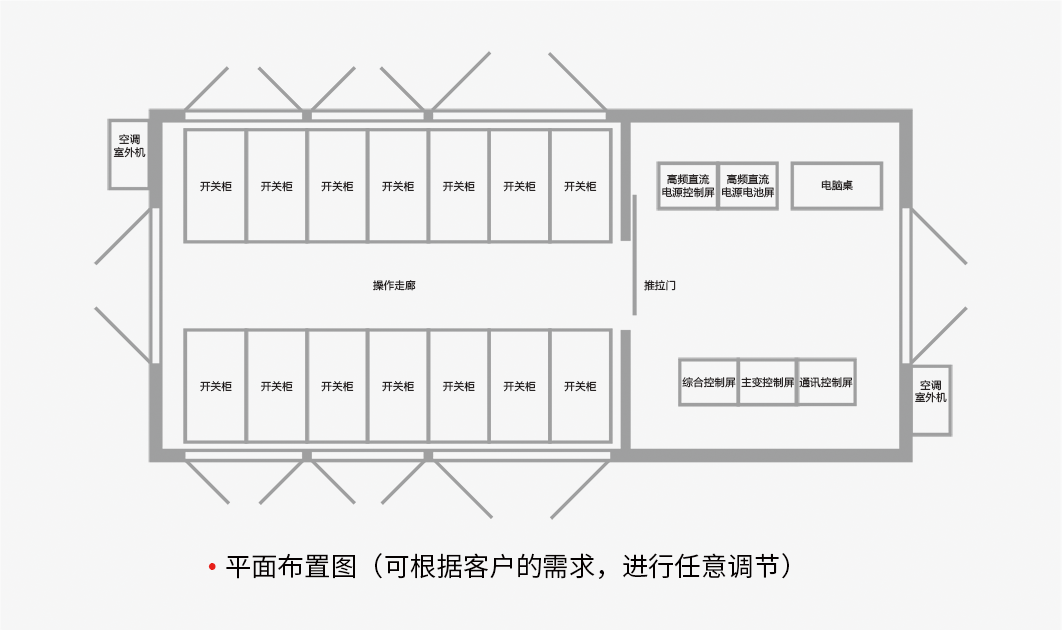

The switchgear station can be configured with a variety of functional units, including:

Incoming unit

Outgoing unit

PT (potential transformer) unit

Station service transformer unit

Tie unit

Metering unit

Integrated automation system

DC power supply system

The number and type of units can be customized according to customer requirements. Equipment configurations may include circuit breakers, disconnectors, current transformers (CTs), voltage transformers (VTs), surge arresters, fuses, and enclosed busbars, as needed.

Cost Saving

The pre-installed substation requires minimal civil works, with total investment costs at approximately 50% of a traditional indoor switchgear station of the same capacity.

Short Construction Period

With simplified foundations and factory pre-assembled and tested equipment, civil works and equipment manufacturing can proceed simultaneously. Upon delivery to the site, the station can be quickly installed and put into operation.

Traditional indoor switchgear station: ~100 days construction period

Pre-installed switchgear station: ~35 days

Reduced Footprint

A typical indoor switchgear station requires ~200㎡ of land. In contrast, a pre-installed large switchgear station only occupies about 80㎡, saving over 60% of space—only 40% of that required by indoor stations.

Factory-Based Construction

The entire primary and secondary systems are assembled and tested in-factory within a sealed enclosure. All functional testing, setting, and commissioning are completed before delivery.

On-site work is limited to foundation preparation, grounding installation, and simple verification tests (mechanical operation & protection testing), enabling standardized, factory-based substation construction and greatly simplifying on-site procedures.

All-Condition Operation

The station features a double-layer, anti-corrosion, thermally insulated, and sealed enclosure, equipped with dual-mode air conditioners and a temperature-humidity control system, ensuring that the equipment operates reliably in an environment comparable to or even better than that of indoor installations.

Integrated Distribution Automation

The station supports full distribution automation, incorporating a microprocessor-based monitoring system, measurement & control units, communication modules, and DC power supply to achieve unattended operation.